Safety sensor recalibration is a critical process for maintaining sensor accuracy and reliability across various applications, from automotive systems to industrial machinery. Over time, environmental factors, wear, or operational changes can cause sensor drift, leading to false readings and missed detections. Regular recalibration adjusts sensor settings to optimal performance levels, ensuring accurate detection and minimizing errors, especially in safety-critical industries like automotive manufacturing and robotics. Top auto body services employ specialized tools and systematic approaches to calibrate collision avoidance, airbag deployment, and lane departure warning systems, enhancing overall vehicle safety.

Safety sensor recalibration is a vital process ensuring the reliability and accuracy of safety systems in various industries. This article delves into the essential practice of recalibrating safety sensors, exploring how it minimizes system errors and maintains optimal performance. We’ll uncover the basics, understand the benefits of regular calibration, and provide best practices for effective implementation, ultimately empowering professionals to navigate potential hazards with confidence. Discover the significance of safety sensor recalibration in preventing future system failures.

- Understanding Safety Sensor Recalibration: The Basics

- How Regular Recalibration Minimizes System Errors

- Best Practices for Effective Safety Sensor Recalibration

Understanding Safety Sensor Recalibration: The Basics

Safety sensor recalibration is a critical process that ensures the accuracy and reliability of safety sensors in various applications, from automotive systems to industrial machinery. These sensors play a pivotal role in detecting potential hazards and triggering appropriate responses to prevent accidents or damage. Over time, however, factors such as environmental conditions, wear and tear, or fluctuations in operational parameters can cause these sensors to drift or become less precise, leading to false readings or missed detections.

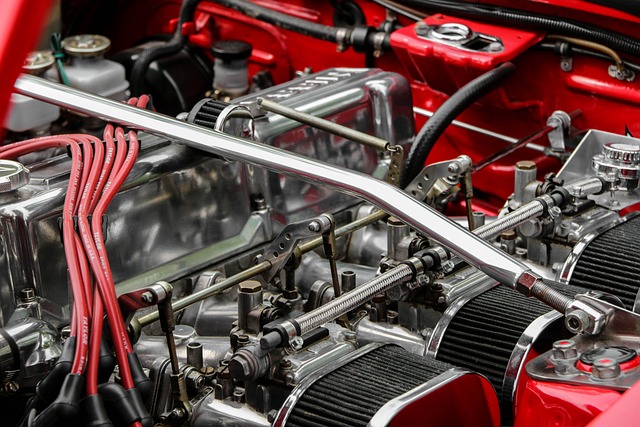

Recalibration involves adjusting the sensor’s settings back to their optimal performance levels, ensuring they accurately detect intended inputs while minimizing false alarms or errors. For instance, in automotive applications, safety sensors like collision avoidance systems or parking aids need regular recalibration to maintain peak performance. Professional car repair services often offer this as a routine maintenance procedure, alongside auto glass repair and car body repair, to keep vehicles safe and reliable on the road.

How Regular Recalibration Minimizes System Errors

Regular safety sensor recalibration is a proactive measure that significantly minimizes system errors in various industries, including automotive. Over time, these sensors, which play a critical role in ensuring safety and precision, can drift out of calibration due to environmental factors, wear and tear, or exposure to extreme conditions. A slight deviation from their original settings can lead to inaccurate readings and subsequently, potential hazards and malfunctioning systems. By scheduling periodic recalibration, professionals in auto body services and body shop services can maintain the sensors’ optimal performance, ensuring they provide accurate data for critical decisions.

This process involves adjusting and fine-tuning the sensors to match current conditions, effectively eliminating any accumulated errors. It is akin to regularly servicing a car’s engine to keep it running smoothly and efficiently. In industries where precision and safety are paramount, such as automotive manufacturing or advanced robotics, this practice is not just recommended but essential. Effective safety sensor recalibration forms a robust quality control measure, preventing costly system failures and ensuring the reliability of operations in both auto body services and body shop services.

Best Practices for Effective Safety Sensor Recalibration

Regular and proper safety sensor recalibration is a best practice for maintaining reliable and accurate vehicle systems. It’s crucial to follow manufacturer guidelines for specific recalibration procedures and intervals, as recommended maintenance schedules can vary by make and model. Prioritize routine checks, especially after potential impacts or shocks, to ensure sensors are functioning optimally. Experienced technicians at top-tier auto body services and vehicle repair shops utilize specialized tools to accurately calibrate various safety systems, including collision avoidance, airbag deployment, and lane departure warnings.

Incorporate a systematic approach for recalibration, starting with identifying sensors that require attention based on vehicle history and condition. Thorough testing should follow to verify sensor performance before and after recalibration, ensuring they operate within specified tolerances. Documentation of the process is essential for tracking maintenance history and facilitating future troubleshooting if needed. By adhering to these best practices for safety sensor recalibration, drivers can have peace of mind knowing their vehicles’ safety systems are prepared to respond swiftly and accurately in unexpected situations, enhancing overall safety on the road.

Safety sensor recalibration is not just a maintenance task; it’s a proactive measure to ensure the reliability and accuracy of safety systems. By regularly calibrating sensors, organizations can minimize false alarms, improve system responsiveness, and prevent potential accidents. Following best practices for recalibration, such as using certified calibration equipment and documenting the process, further enhances the effectiveness of this critical procedure. Investing in proper safety sensor recalibration is a game-changer, fostering a safer and more efficient working environment.